How it works.

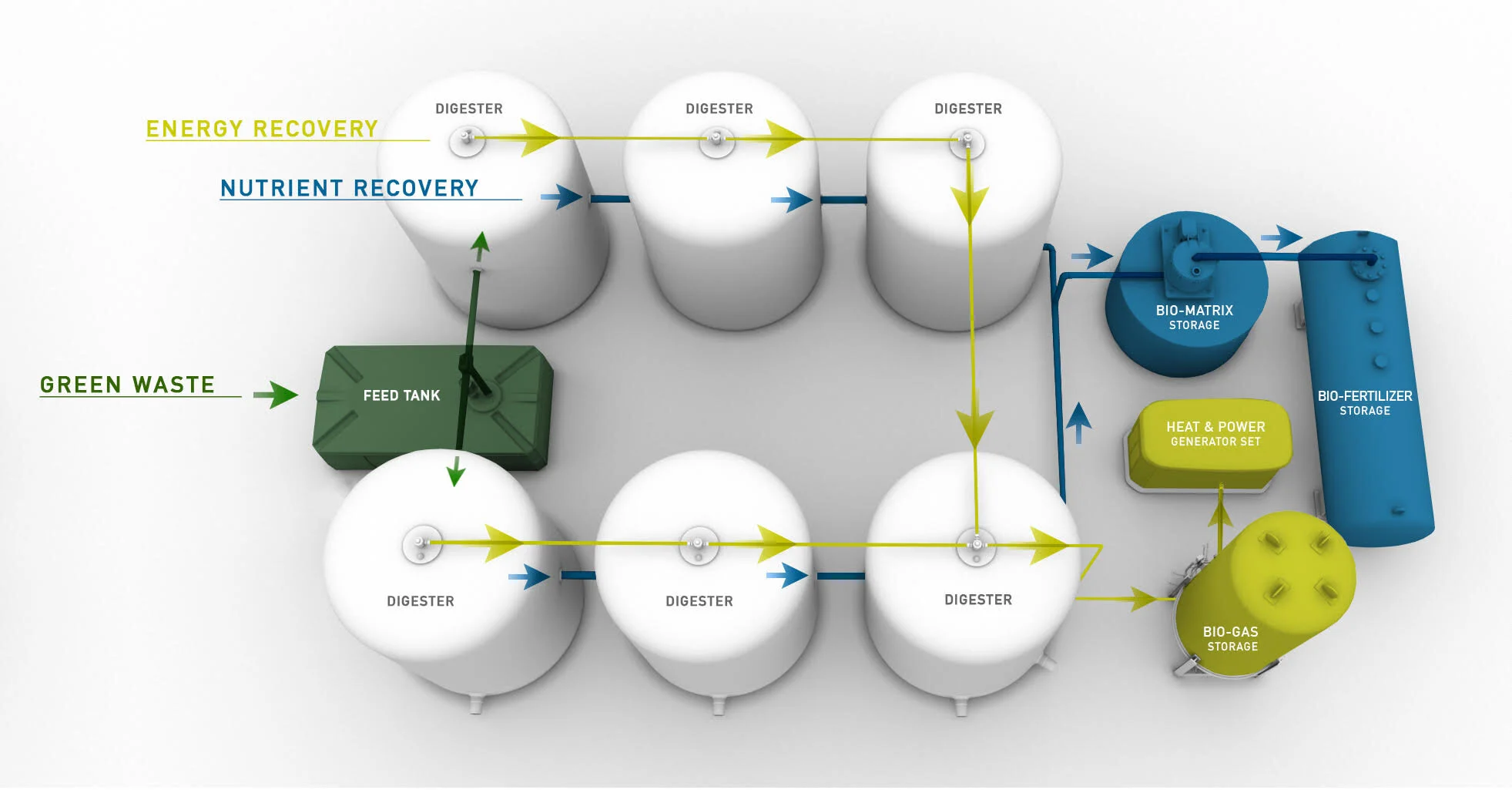

The process of transforming a liability into assets begins once organic waste is put into the feed tank.

A robust chopping system mechanically breaks down the organic material allowing it to be pumped through a volume control valve, alternating flow to each of the primary Digesters on either side of the Feed Tank.

Once in the oxygen free environment, organics begin the process of Anaerobic Digestion in which microbes breakdown and separate the gas from the liquid and solid medium known as ‘digestate slurry’.

This process continues through the second and third Digesters on each side of the Feed Tank.

As gas (i.e. Bio-Gas) rises to the top of the Digester tank it is captured and cleaned before being stored in a cryogenic holding tank for utility use as a heating and/or equipment fuel or further conversion to electrical power through a Combined Heat & Power generator set.

Similarly, the digestate slurry moves through the lower set of pipes between Digesters before it is separated by centrifuge into its solid and liquid phases.

The solid (i.e. Bio-Matrix) is stored in a stabilization vessel for final curing. Bio Matrix can be used as a crop growth medium, thermal fuel source, or animal bedding.

The remaining nutrient rich liquid (i.e. Bio-Fertilizer) is filtered and moved into a storage tank where it can be integrated into an irrigation or manual watering system.

Depending on utility needs, various system combinations can be integrated to support operations and achieve desired outputs.